1. Introducció

This manual provides essential instructions for the safe and effective operation, setup, and maintenance of the JIT 900 Geomembrane Hot Wedge Welder. The JIT 900 is designed for welding geomembrane materials, creating strong, consistent seams for various applications. Please read this manual thoroughly before operating the machine to ensure proper use and to prevent injury or damage.

2. Instruccions de seguretat

Always prioritize safety when operating any machinery. Failure to follow these safety guidelines may result in serious injury or equipment damage.

2.1 Seguretat general

- Llegiu i enteneu totes les instruccions d'aquest manual abans de l'operació.

- Només personal qualificat i autoritzat ha d'utilitzar aquest equip.

- Mantenir la zona de treball neta i ben il·luminada. Les zones desordenades o fosques conviden a accidents.

- No feu funcionar la màquina en atmosferes explosives, com ara en presència de líquids, gasos o pols inflamables.

- Wear appropriate personal protective equipment (PPE), including safety glasses, gloves, and hearing protection, as required.

2.2 Seguretat elèctrica

- Assegureu-vos que la font d'alimentació coincideixi amb els requisits de la màquina (220 V, 50 Hz).

- Always connect the machine to a properly grounded outlet.

- Inspeccioneu el cable d'alimentació i l'endoll per detectar danys abans de cada ús. No l'utilitzeu si està danyat.

- Never operate the machine in wet conditions or with wet hands.

- Desconnecteu l'alimentació abans de realitzar qualsevol manteniment o ajust.

2.3 Seguretat de funcionament

- The welding wedge and surrounding components become extremely hot during operation (up to 450°C). Avoid direct contact.

- Mantingueu les mans i la roba solta allunyades de les peces mòbils, especialment dels rodets.

- Ensure proper ventilation in the work area to dissipate any fumes produced during welding.

- Secure the geomembrane material to prevent unexpected movement during welding.

3. Producte acabatview

The JIT 900 Geomembrane Hot Wedge Welder is a robust and efficient tool for creating high-quality seams in various geomembrane materials. Its design focuses on precision and ease of use.

Figura 1: This image displays the JIT 900 Geomembrane Hot Wedge Welder from a top-down perspective, showing its main body, control panel, handle, and welding mechanism.

Components clau:

- Tauler de control: Features digital temperature display, power switch, fuse, and speed adjustment.

- Mànec: Ergonomically designed for easy maneuvering and transport.

- Welding Head: Contains the heated wedge and pressure rollers for sealing.

- Engagement Lever: Used to engage and disengage the welding rollers with the material.

- Guies de materials: Ensure proper alignment of geomembrane sheets.

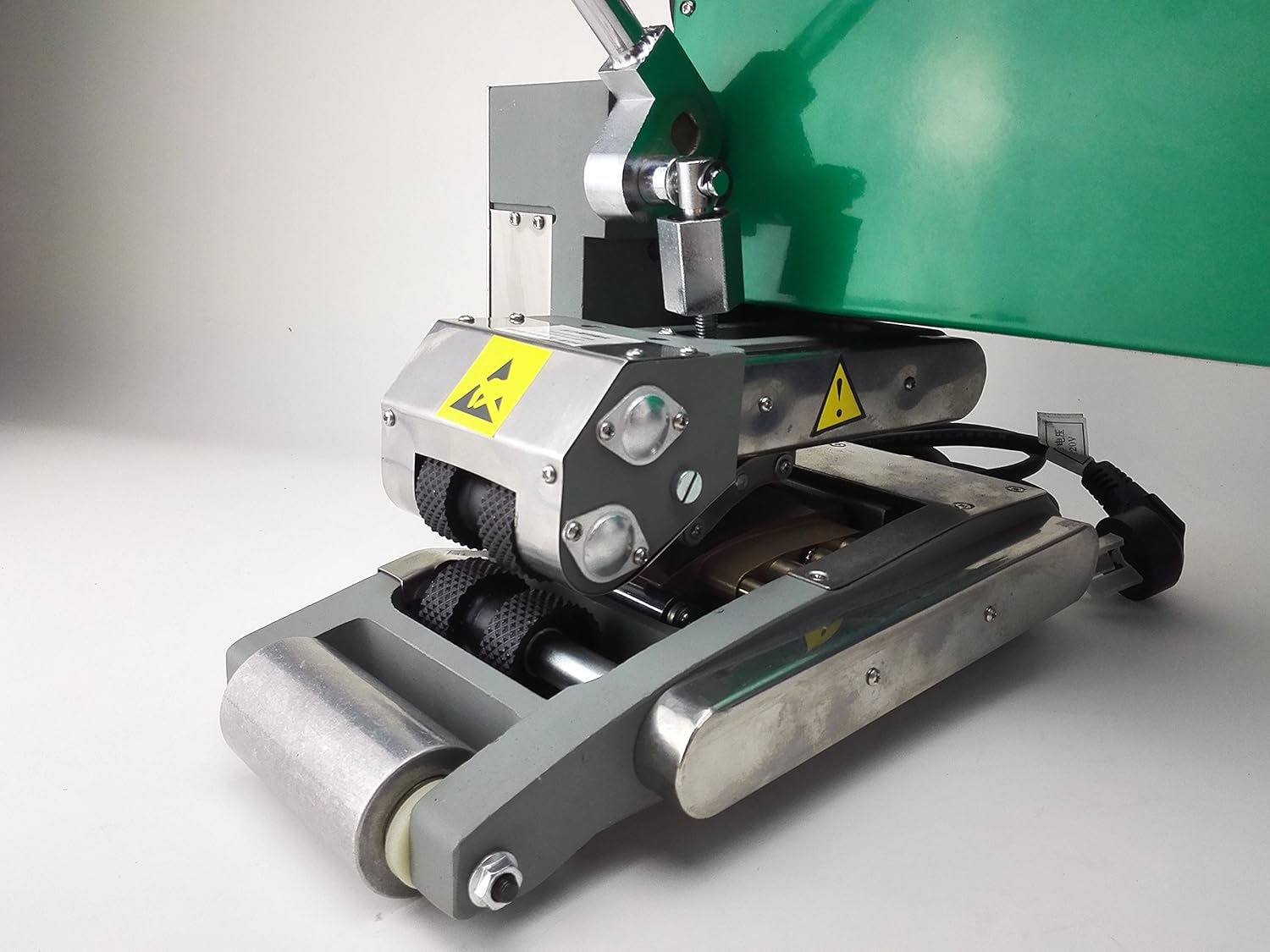

Figura 2: Un detallat view of the welding head of the JIT 900, highlighting the heated wedge, pressure rollers, and material guides crucial for creating strong seams.

4. Especificacions tècniques

| Paràmetre | Valor |

|---|---|

| Vol. De sortidatage | 220 V |

| Freqüència | 50 Hz |

| Poder | 1800 W |

| Velocitat de soldadura | 0.5 ~ 5 m/min |

| Rang de temperatura de calefacció | 0 ~ 450 °C (with temperature showing function) |

| Gruix del material de soldadura | 1.0 mm ~ 3.0 mm (single membrane thickness) |

| Amplada de soldadura | 14 mm x 2 (Interior Cavity: 16 mm) |

| Welding Intention | > 85% Maternity material (Resistance to the direction of cutting) |

| Amplada de la junta | 120 mm |

| Machine Body Weight | 13 KG (aprox. 28.6 lliures) |

| Pes de l'article (enviament) | 42.5 lliures |

| Dimensions del paquet | 18.3 x 14.9 x 14 polzades |

5. Configuració

Una configuració adequada és crucial per a un rendiment i una seguretat òptims.

5.1 Desembalatge i inspecció

- Carefully remove the welder from its packaging.

- Inspect the machine for any visible damage that may have occurred during shipping. Report any damage to the supplier immediately.

- Assegureu-vos que hi hagi tots els components que figuren a la llista d'embalatge.

Figura 3: The durable silver carrying case designed to protect and transport the JIT 900 Geomembrane Hot Wedge Welder, featuring secure latches and a top handle.

5.2 Connexió d'alimentació

- Ensure the power switch on the control panel is in the 'OFF' position.

- Connecteu el cable d'alimentació a la màquina.

- Connecteu el cable d'alimentació a una presa de corrent de 220 V i 50 Hz amb connexió a terra.

5.3 Preparació del material

- Clean the geomembrane surfaces to be welded, ensuring they are free from dust, dirt, moisture, and oil.

- Overlap the two geomembrane sheets according to the required seam width (typically 120mm joint width). Ensure the overlap is consistent and smooth.

- Secure the material to prevent shifting during the welding process.

6. Funcionament

Follow these steps for effective welding with the JIT 900.

Figura 4: A close-up of the control panel, showing the digital temperature display, power switch, fuse, and speed adjustment knob, labeled 'Geomembrane Welding Machine Model: 900 Voltage: 220 Power: 1800W'.

6.1 Engegada i configuració inicial

- Turn the main power switch to the 'ON' position. The digital display will illuminate.

- Set the desired welding temperature using the temperature control knob. Refer to the geomembrane manufacturer's recommendations for optimal welding temperature, typically between 0-450°C. Allow the machine to preheat until the set temperature is reached and stable.

- Adjust the welding speed using the speed control knob. Start with a lower speed (e.g., 1-2 m/min) and adjust as needed based on material thickness and desired weld quality.

6.2 Procés de soldadura

- Position the welder at the start of the seam, ensuring the geomembrane sheets are correctly aligned under the welding head and guides.

- Lower the engagement lever to bring the pressure rollers into contact with the geomembrane, applying even pressure.

- The machine will automatically begin to move forward, heating and pressing the geomembrane layers together to form a weld.

- Monitor the welding process to ensure consistent speed and temperature. Adjust settings if the weld quality is not satisfactory.

- At the end of the seam, lift the engagement lever to disengage the rollers and stop the welding process.

6.3 Post-Welding Inspection

- Visually inspect the welded seam for consistency, absence of gaps, and proper fusion.

- Perform peel tests or shear tests on test welds to verify weld strength and integrity, especially when starting a new project or changing material types.

7. Manteniment

Regular maintenance ensures the longevity and reliable performance of your JIT 900 welder.

7.1 Neteja

- After each use, ensure the machine is powered off and cooled down.

- Clean the welding wedge and rollers to remove any accumulated plastic residue or debris. Use a non-abrasive cloth and, if necessary, a suitable solvent recommended by the geomembrane manufacturer.

- Wipe down the exterior of the machine to keep it free from dust and dirt.

7.2 Inspecció

- Regularly inspect the power cord for cuts, fraying, or other damage.

- Check the condition of the welding wedge and rollers for wear or damage. Replace worn components as needed.

- Assegureu-vos que tots els elements de fixació estiguin ben ajustats.

7.3 Emmagatzematge

- Store the welder in its protective carrying case in a dry, clean environment when not in use.

- Avoid storing in areas with extreme temperatures or high humidity.

8. Solució De Problemes

Aquesta secció tracta els problemes habituals que podeu trobar durant el funcionament.

8.1 Machine Does Not Power On

- Comproveu la connexió d'alimentació: Ensure the power cord is securely plugged into both the machine and a live 220V outlet.

- Comproveu el fusible: Inspect the fuse on the control panel (refer to Figure 4). If blown, replace it with a fuse of the correct rating.

- Interruptor principal d’alimentació: Confirm the main power switch is in the 'ON' position.

8.2 Poor Weld Quality (e.g., weak seam, burn-through)

- Configuració de la temperatura: Adjust the welding temperature. Too low a temperature results in a weak weld; too high can cause burn-through. Refer to material specifications.

- Welding Speed: Adjust the welding speed. Slower speeds allow more heat transfer; faster speeds reduce it.

- Material Cleanliness: Ensure the geomembrane surfaces are clean and free of contaminants.

- Roller Pressure: Verify that the pressure rollers are applying adequate and even pressure.

- Components desgastats: Inspect the welding wedge and rollers for wear. Worn components can lead to inconsistent welds.

8.3 Machine Not Moving or Irregular Movement

- Engagement Lever: Ensure the engagement lever is fully lowered to engage the drive mechanism.

- Configuració de velocitat: Check the speed control knob setting.

- Obstruccions: Inspect the path of the machine and the rollers for any obstructions or debris.

For issues not covered here, or if troubleshooting steps do not resolve the problem, contact customer support.

9. Garantia i Suport

The JIT 900 Geomembrane Hot Wedge Welder comes with a garantia d'un any from the date of purchase, covering manufacturing defects. This warranty does not cover damage resulting from misuse, neglect, unauthorized modifications, or normal wear and tear.

For technical assistance, warranty claims, or to order replacement parts, please contact your authorized JIT dealer or customer support. When contacting support, please have your product model (JIT 900) and purchase information readily available.