1. Introducció

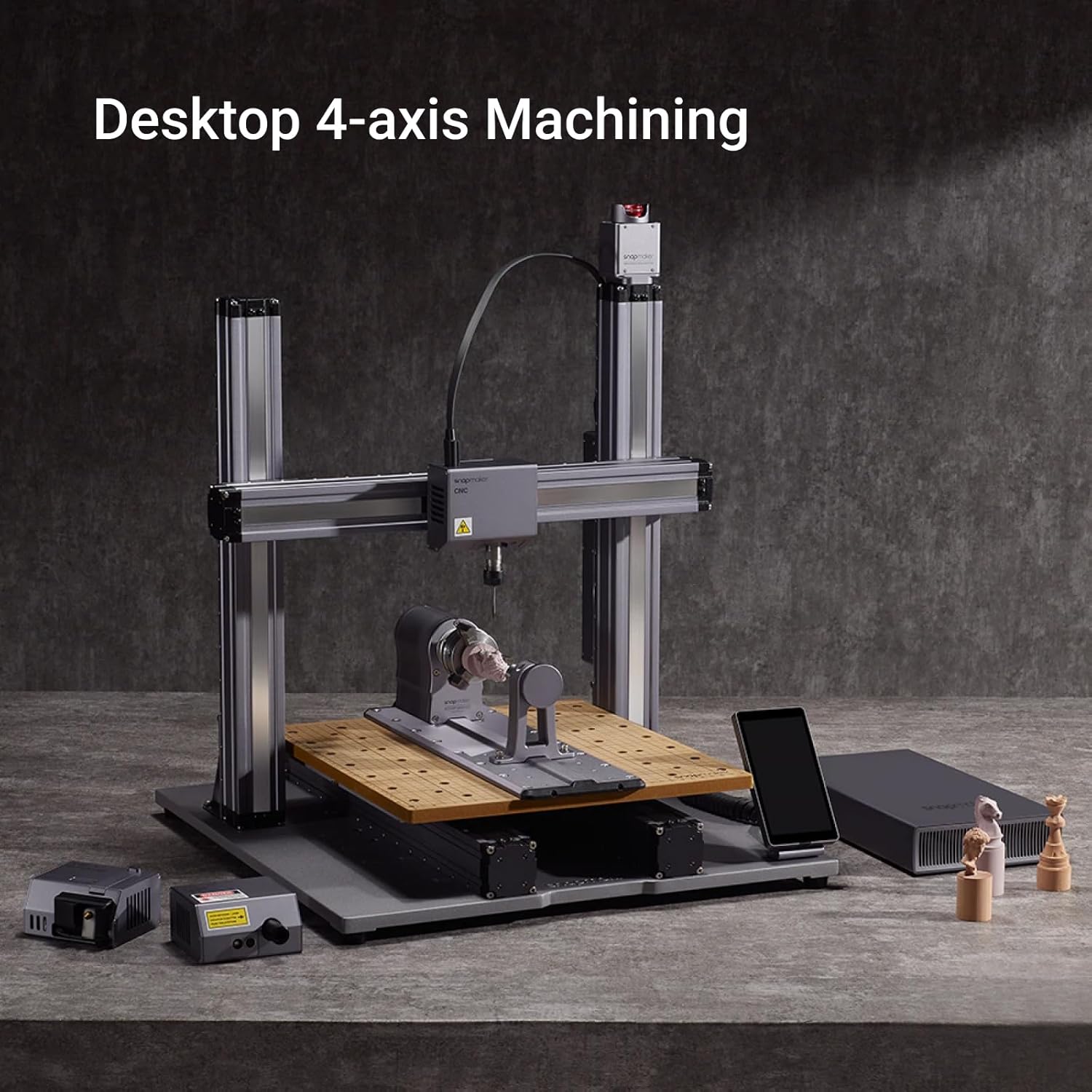

This manual provides detailed instructions for the installation, operation, and maintenance of your Snapmaker 2.0 Rotary Module A350T. The Rotary Module enhances your Snapmaker 2.0 machine by enabling 4-axis CNC carving and laser engraving on cylindrical and irregular objects. Please read this manual thoroughly before using the product to ensure safe and efficient operation.

2. Producte acabatview

The Snapmaker 2.0 Rotary Module A350T is designed to integrate seamlessly with your Snapmaker 2.0 system, expanding its capabilities to include rotary machining. It features a robust construction and precise mechanics for high-quality results.

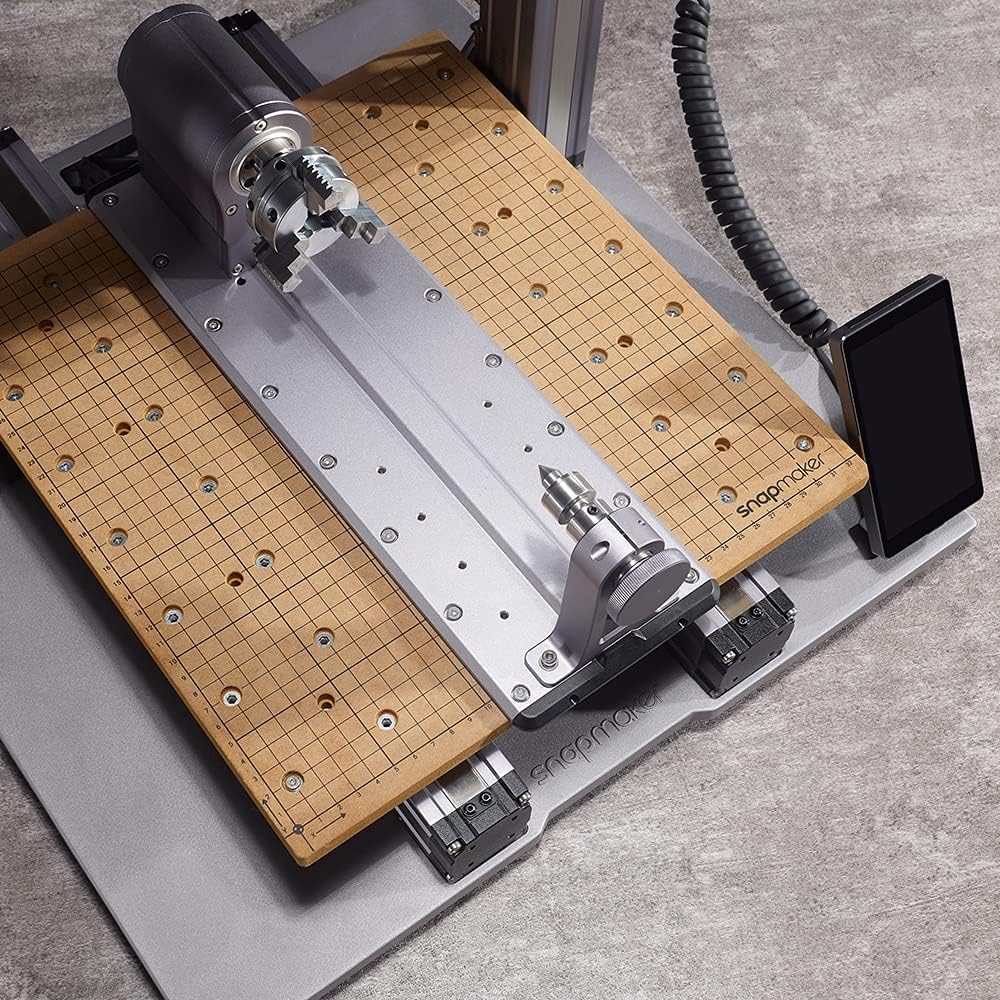

Image 2.1: The Snapmaker 2.0 Rotary Module A350T, showing the headstock with a 3-jaw chuck and the tailstock.

Característiques principals:

- 4th Dimension Machining: Enables rotary CNC carving and laser engraving on uneven and irregular surfaces.

- Strain Wave Gearing: Incorporates a 100:1 speed reducer for precise rotation and minimal angle control (0.1°).

- Alta precisió: Capable of producing detailed three-dimensional artworks and small-sized sculptures.

- Suport de programari: Fully supported by Snapmaker Luban for 4-axis projects, including STL file import and advanced 4-axis linkage.

3. Configuració i instal·lació

Proper installation of the Rotary Module is crucial for optimal performance. Follow these steps carefully.

3.1 Desembalatge i identificació de components

Carefully unpack all components and verify against the packing list. Ensure all parts are present and undamaged.

Imatge 3.1: acabatview of the Rotary Module components, including the headstock, tailstock, and base plate.

3.2 Muntatge del mòdul rotatiu

- Ensure your Snapmaker 2.0 machine is powered off and disconnected from the power source.

- Remove the existing wasteboard or work platform from your Snapmaker 2.0.

- Align the Rotary Module's base plate with the mounting holes on the Snapmaker 2.0's platform. The base plate has holes on both sides, allowing for flexible positioning of the headstock and tailstock.

- Secure the Rotary Module to the machine using the provided screws and tools. Ensure it is firmly attached and does not wobble.

- Connect the Rotary Module cable to the designated port on your Snapmaker 2.0 controller.

Image 3.2: A Snapmaker 2.0 machine with the Rotary Module correctly installed for 4-axis machining.

Imatge 3.3: De dalt a baix view illustrating the Rotary Module's placement on the Snapmaker 2.0 work platform.

4. Instruccions de funcionament

This section details the operational aspects of the Rotary Module for CNC carving and laser engraving.

4.1 Software Setup (Snapmaker Luban)

The Snapmaker Luban software is essential for preparing and executing 4-axis projects. Ensure you have the latest version installed.

- Launch Snapmaker Luban and select the 4-axis CNC or Rotary Laser engraving workspace.

- Import your 3D model (e.g., STL files) into the software.

- Configure the project settings, including material type, toolpaths, and rotation parameters. Luban supports advanced 4-axis linkage, allowing simultaneous movement of X, Y, Z, and B axes.

- Generate the G-code and transfer it to your Snapmaker 2.0 machine.

Image 4.1: Screenshot of Snapmaker Luban software demonstrating 4-axis project setup and preview.

4.2 Loading Workpieces

Securely mount your workpiece onto the Rotary Module's 3-jaw chuck and tailstock.

- Open the jaws of the 3-jaw chuck and insert one end of your cylindrical workpiece.

- Tighten the chuck jaws to firmly grip the workpiece.

- Adjust the tailstock to support the other end of the workpiece, ensuring it is centered and stable. The tailstock center holds objects securely in place.

- Verify that the workpiece is level and securely held before starting any operation.

Image 4.2: Diagram illustrating the secure mounting of a workpiece using the 3-jaw chuck and tailstock.

4.3 Rotary CNC Carving

The Rotary Module excels at creating intricate three-dimensional objects.

- Supported materials for CNC carving include wood, tooling and modeling board, plastic, bamboo, and wax.

- The module offers 360° continuous rotation with a maximum angular speed of 45° per second.

- Precise control options are available on the touchscreen, ranging from 0.2, 1, and 5-degree rotations.

Imatge 4.3: Un example of rotary CNC carving creating a detailed sculpture from a block of material.

4.4 Rotary Laser Engraving

Utilize the Rotary Module for precise laser engraving on cylindrical objects.

- Supported materials for laser engraving include wood, leather, plastic, fabric, paper, and non-transparent acrylic.

- Ensure proper safety precautions are taken when operating the laser module, including wearing protective eyewear.

Image 4.4: A wooden cylinder undergoing rotary laser engraving, showcasing intricate design capabilities.

5. Manteniment

Regular maintenance ensures the longevity and optimal performance of your Rotary Module.

5.1 Neteja

- After each use, especially after CNC carving, clean any dust, chips, or debris from the module using a soft brush or compressed air.

- Wipe down the exterior surfaces with a dry, lint-free cloth. Avoid using harsh chemicals or abrasive materials.

5.2 Lubricació

- Periodically check the moving parts, such as the chuck jaws and tailstock mechanism, for smooth operation.

- Apply a small amount of light machine oil or grease to these components if necessary, following the recommendations in the main Snapmaker 2.0 manual.

5.3 Inspecció

- Regularly inspect all screws and connections to ensure they are tight. Retighten any loose fasteners.

- Check cables for any signs of wear or damage. Replace damaged cables immediately.

6. Solució De Problemes

This section addresses common issues you might encounter with the Rotary Module.

6.1 Rotary Module Not Responding

- Comproveu les connexions: Ensure the Rotary Module cable is securely connected to both the module and the Snapmaker 2.0 controller.

- Reconeixement de programari: Verify that Snapmaker Luban recognizes the Rotary Module. Restart the software and the machine if necessary.

- Actualització del firmware: Ensure your Snapmaker 2.0 and Rotary Module have the latest firmware installed.

6.2 Inaccurate Machining/Engraving

- Estabilitat de la peça: Ensure the workpiece is firmly secured in both the 3-jaw chuck and the tailstock. Any movement can lead to inaccuracies.

- Calibració: Perform a calibration check for the Rotary Module if available in the Snapmaker Luban software or machine settings.

- Tool/Laser Focus: For CNC, ensure the carving bit is sharp and correctly installed. For laser, verify the laser focus is properly set for the material.

- G-code Errors: Review your G-code and project settings in Snapmaker Luban for any potential errors or incorrect parameters.

6.3 Excessive Noise or Vibration

- Components solts: Check all mounting screws and ensure the Rotary Module is securely attached to the Snapmaker 2.0 platform.

- Workpiece Imbalance: An unbalanced workpiece can cause vibrations. Ensure the workpiece is as centered as possible.

- Lubricació: Apply lubrication to moving parts as described in the Maintenance section if they appear dry or stiff.

7. Especificacions

Detailed technical specifications for the Snapmaker 2.0 Rotary Module A350T.

| Característica | Especificació |

|---|---|

| Fabricant | Snapmaker |

| Número de part | 71012 |

| Pes de l'article | 9.88 lliures |

| Dimensions del paquet | 18.75 x 9 x 9 polzades |

| Mida | Artisan/A350T Rotary Module |

| Gearing Type | Strain Wave Gearing |

| Relació del reductor de velocitat | 100:1 |

| Minimum Angle Control | 0.1° |

| Velocitat angular màxima | 45° per segon |

8. Garantia i Suport

For warranty information and technical support, please refer to the official Snapmaker weblloc web o contacteu directament amb el seu servei d'atenció al client.

- Oficial Weblloc: Visita www.snapmaker.com for the latest support resources, FAQs, and contact information.

- Atenció al client: For specific issues or warranty claims, please reach out to Snapmaker's customer support team through their weblloc.