1. Introducció

The LAUNCH SmartSafe CNC605A is a professional ultrasonic fuel injector cleaner and tester designed for comprehensive maintenance of GDI, EFI, and SFI injector systems. This manual provides essential information for the safe and effective operation, maintenance, and troubleshooting of your device. Please read this manual thoroughly before operating the unit.

Imatge 1.1: Frontal view of the LAUNCH SmartSafe CNC605A unit, showcasinel seu disseny compacte i el panell de control.

2. Característiques i funcions principals

The CNC605A offers a range of advanced features to ensure thorough cleaning and accurate testing of fuel injectors:

- Neteja per ultrasons: Utilizes powerful ultrasonic technology to completely remove carbon deposits from fuel injectors.

- Uniformity and Sprayability Test: Evaluates the injection quantity uniformity of each nozzle and observes the spray pattern with backlight assistance.

- Prova de segellat: Checks for leaks and proper sealing of the fuel injection nozzle under specified pressure.

- Injection Volume Test: Measures the injection volume of the fuel injector over a set duration of continuous spraying.

- No Disassembly Needed (for EFI and SFI): Enables cleaning of EFI and SFI fuel injectors and the fuel supply system directly on the vehicle without removal.

- Mode automàtic: Features a preset program for automated testing of fuel injection nozzles.

- Automatic Liquid Discharge: Automatically discharges liquid from the glass tubes when a predetermined value is reached, enhancing efficiency and safety compared to manual discharge systems.

Imatge 2.1: acabatview of the CNC605A's adaptable multiple fuel injectors, powerful ultrasonic cleaning, simulation condition test, and automatic oil discharge capabilities.

Image 2.2: Visual representation of the core functions: Ultrasonic Cleaning, Uniformity & Atomization Test, Sealing Test, Injection Volume Test, No Disassembly Needed, and Automatic Mode.

3. Components i accessoris del producte

3.1 Components de la unitat principal

Familiarize yourself with the main components of the CNC605A unit:

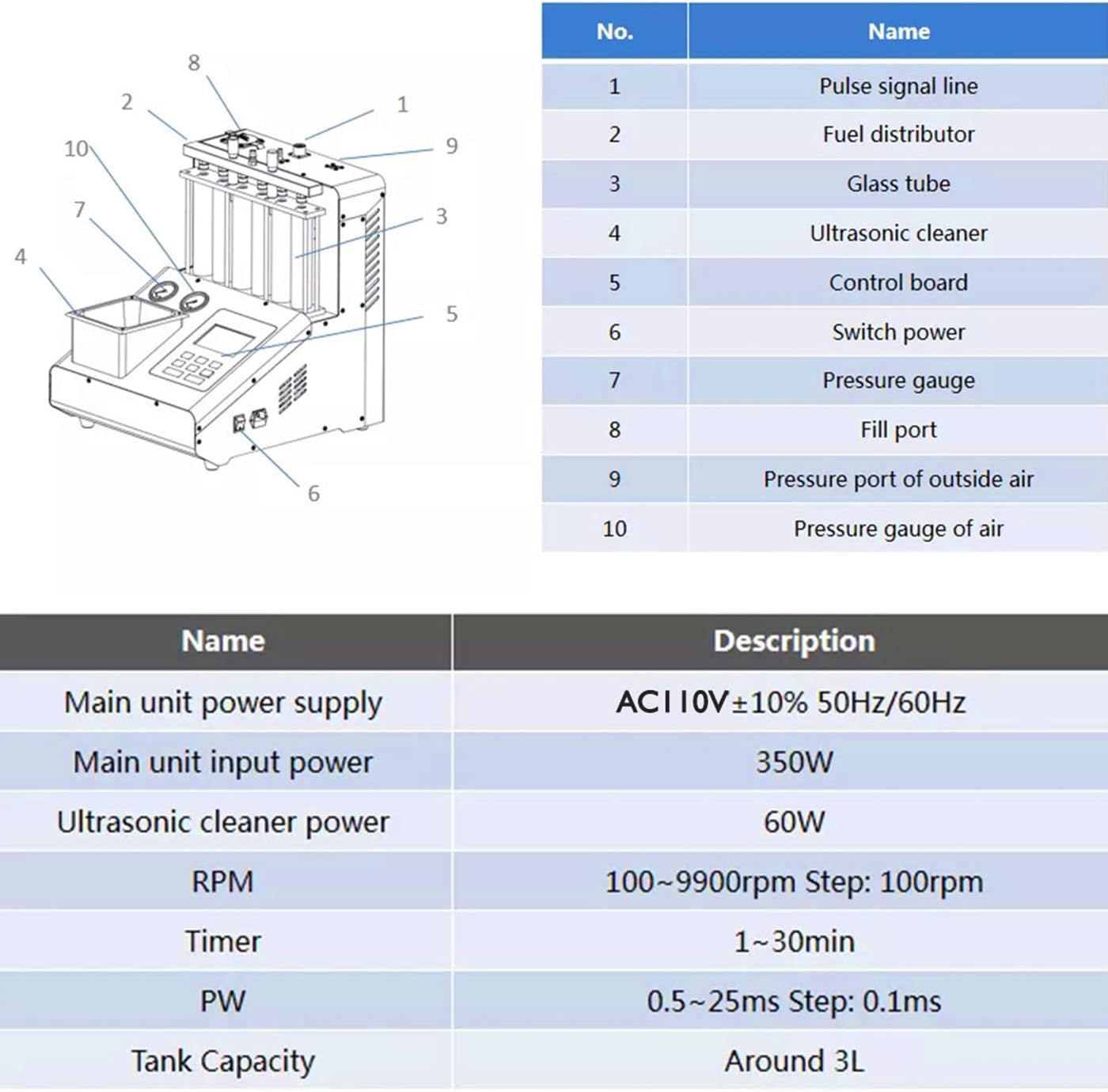

Image 3.1: Labeled diagram of the CNC605A main unit, indicating key parts such as pulse signal line, fuel distributor, glass tubes, ultrasonic cleaner, and control board.

| No. | Nom |

|---|---|

| 1 | Pulse signal line |

| 2 | Fuel distributor |

| 3 | Tub de vidre |

| 4 | Netejador d'ultrasons |

| 5 | Tauler de control |

| 6 | Canvia l'alimentació |

| 7 | Manòmetre |

| 8 | Port d'ompliment |

| 9 | Pressure port of outside air |

| 10 | Pressure gauge of air |

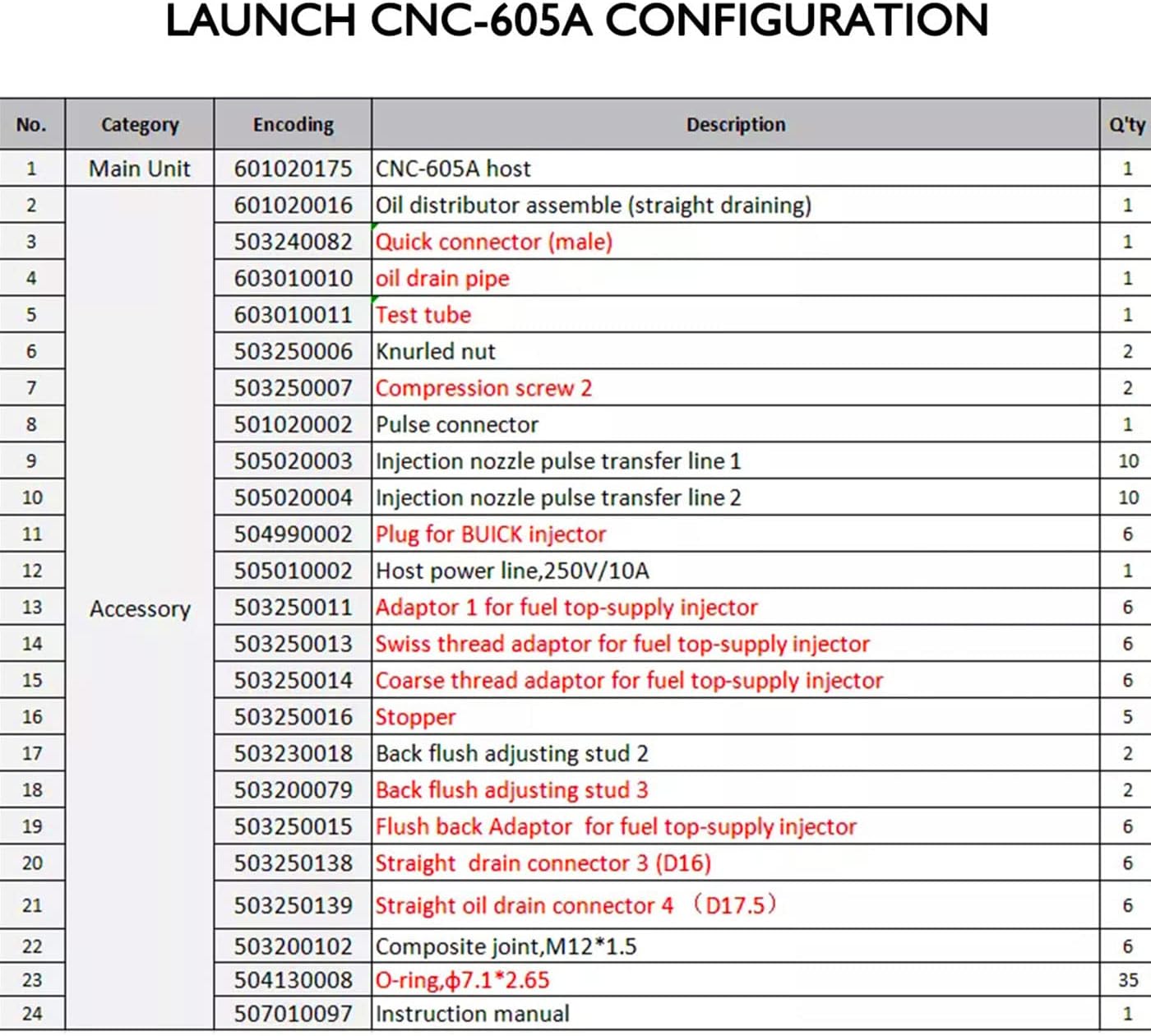

3.2 Accessoris inclosos

The CNC605A comes with a comprehensive set of accessories to support various injector types and cleaning procedures:

Image 3.2: Detailed list of the CNC605A's main unit and included accessories, such as oil distributor assembly, quick connectors, various adaptors, O-rings, and the instruction manual.

| No. | Categoria | Descripció | Quantitat |

|---|---|---|---|

| 1 | Unitat principal | CNC-605A host | 1 |

| 2 | Oil distributor assembly (straight draining) | 1 | |

| 3 | Quick connector (male) | 1 | |

| 4 | Tub de drenatge d'oli | 1 | |

| 5 | Tub d'assaig | 1 | |

| 6 | Knurled nou | 2 | |

| 7 | Compression screw 2 | 2 | |

| 8 | Pulse connector | 1 | |

| 9 | Injection nozzle pulse transfer line 1 | 10 | |

| 10 | Injection nozzle pulse transfer line 2 | 10 | |

| 11 | Plug for BUICK injector | 6 | |

| 12 | Host power line, 250V/10A | 1 | |

| 13 | Accessoris | Adaptor 1 for fuel top-supply injector | 6 |

| 14 | Swiss thread adaptor for fuel top-supply injector | 6 | |

| 15 | Coarse thread adaptor for fuel top-supply injector | 6 | |

| 16 | Tap | 5 | |

| 17 | Back flush adjusting stud 2 | 2 | |

| 18 | Back flush adjusting stud 3 | 2 | |

| 19 | Flush back Adaptor for fuel top-supply injector | 6 | |

| 20 | Straight drain connector 3 (D16) | 6 | |

| 21 | Straight oil drain connector 4 (D17.5) | 6 | |

| 22 | Composite joint, M12*1.5 | 6 | |

| 23 | O-ring, φ7.1*2.65 | 35 | |

| 24 | Manual d'instruccions | 1 |

4. Especificacions tècniques

The following are the technical parameters for the LAUNCH SmartSafe CNC605A:

| Nom | Descripció |

|---|---|

| Font d'alimentació | AC110V 50Hz |

| Main Engine Power | 350W |

| Potència per ultrasons | 60W |

| Pressió del combustible | 0.1-10 bar |

| Pressió d'entrada d'aire | 5-8 bar |

| RPM | 100-9900rpm (Step: 100rpm) |

| PW (amplada de pols) | 0.5-25.0ms (Step: 0.1ms) |

| Interval del temporitzador | 1-30 min |

| Capacitat del dipòsit | ~ 3L |

| Material del cos | Alumini |

| Tipus d'ajust | Ajuste universal |

5. Informació de seguretat

Always adhere to safety precautions when operating the CNC605A to prevent injury or damage to the equipment.

- Ensure the unit is placed on a stable, level surface in a well-ventilated area.

- Do not operate the unit near open flames or sources of ignition due to the presence of flammable liquids.

- Wear appropriate personal protective equipment (PPE), including safety glasses and chemical-resistant gloves, when handling cleaning fluids and fuel.

- Always disconnect the power supply before performing any maintenance or cleaning on the unit.

- Use only recommended cleaning and testing fluids. Refer to the fluid manufacturer's safety data sheets (SDS).

- Avoid direct contact with ultrasonic cleaning fluid and fuel. In case of contact, wash thoroughly with soap and water.

- No submergiu la unitat principal en aigua o altres líquids.

- Mantingueu els nens i el personal no autoritzat allunyats de la zona d'operació.

6. Configuració i instal·lació

Follow these steps for initial setup of your CNC605A unit:

- Desembalatge: Carefully remove all components from the packaging. Verify that all items listed in Section 3.2 are present and undamaged.

- Col·locació: Position the unit on a sturdy workbench in a well-ventilated workshop. Ensure there is adequate space around the unit for operation and maintenance.

- Connexió d'alimentació: Connect the provided power cable to the unit's power inlet (No. 12 in Image 3.1) and then to a grounded AC110V 50Hz power outlet.

- Connexió de subministrament d'aire: Connect an external air compressor (5-8 bar) to the air inlet pressure port (No. 9 in Image 3.1) using appropriate fittings.

- Ompliment de fluids: Fill the ultrasonic cleaner tank (No. 4 in Image 3.1) with the recommended ultrasonic cleaning fluid. Fill the fuel tank (accessible via Fill port No. 8) with the appropriate testing fluid (e.g., calibration fluid or gasoline substitute). Note: Cleaning and testing liquids are not included and must be purchased separately.

- Instal·lació d'injectors: Install the desired fuel injectors into the fuel distributor (No. 2 in Image 3.1) using the appropriate adaptors and O-rings from the accessory kit. Ensure secure connections to prevent leaks.

- Pulse Line Connection: Connect the pulse signal lines (No. 1 and No. 9/10) from the control board to each injector.

Image 6.1: Multiple views of the CNC605A, illustrating the layout of the GDI injector area, air intake, outlet, pulse signal connections, and power switch.

7. Instruccions de funcionament

The CNC605A offers various modes for comprehensive injector testing and cleaning. Use the control board (No. 5 in Image 3.1) to navigate and select functions.

7.1 Neteja per ultrasons

- Col·loqueu els injectors al dipòsit de neteja per ultrasons.

- Ensure the injectors are fully submerged in the ultrasonic cleaning fluid.

- Seleccioneu el mode "Neteja per ultrasons" al tauler de control.

- Set the desired cleaning time (1-30 minutes).

- Start the cleaning process. The ultrasonic waves will dislodge carbon deposits.

7.2 Uniformity and Sprayability Test

- Install the injectors into the test tubes (No. 3 in Image 3.1).

- Select 'Uniformity & Sprayability Test' mode.

- Adjust parameters such as RPM and pulse width (PW) to simulate engine conditions.

- Observe the spray pattern and volume in each glass tube. Look for consistent spray cones and equal fluid levels.

7.3 Sealing Test

- With injectors installed in the test tubes, select 'Sealing Test' mode.

- The system will apply a specific pressure.

- Observe the injectors for any signs of leakage or dripping over a set period.

7.4 Injection Volume Test

- Select 'Injection Volume Test' mode.

- Set the duration for continuous spraying.

- After the test, compare the fluid levels in the glass tubes to determine the injection volume of each injector.

7.5 No Disassembly Needed (EFI & SFI)

This function allows for on-vehicle cleaning of EFI and SFI injectors and the fuel supply system. Refer to the specific instructions for connecting the unit to the vehicle's fuel system without removing the injectors.

7.6 Mode automàtic

For streamlined testing, select 'Automatic Mode'. The unit will execute a preset program covering various tests. This mode is ideal for quick diagnostics and batch testing.

8. Manteniment

Regular maintenance ensures the longevity and optimal performance of your CNC605A.

- Gestió de fluids: Regularly drain and replace old cleaning and testing fluids. Dispose of used fluids according to local environmental regulations.

- Neteja de la unitat: Netegeu l'exterior de la unitat amb un drap suau i sec.amp tela. Eviteu utilitzar netejadors abrasius o dissolvents.

- Glass Tubes: Clean the glass test tubes after each use to ensure accurate readings and prevent cross-contamination.

- Inspecció del filtre: Periodically inspect any inline filters for debris and replace them if necessary.

- Emmagatzematge: When not in use, store the unit in a clean, dry environment, protected from dust and extreme temperatures.

9. Solució De Problemes

This section addresses common issues you might encounter with the CNC605A.

| Problema | Causa possible | Solució |

|---|---|---|

| La unitat no s'encén | Power cable disconnected; Power outlet fault; Unit fuse blown | Check power cable connection; Test power outlet; Inspect and replace fuse if necessary |

| No fluid spray from injectors | No testing fluid in tank; Air pressure too low; Injectors clogged; Pulse lines disconnected | Fill testing fluid; Check air compressor and connections; Perform ultrasonic cleaning; Reconnect pulse lines securely |

| Inconsistent spray pattern/volume | Injectors still dirty/clogged; Faulty injector; Incorrect test parameters | Repeat ultrasonic cleaning; Replace faulty injector; Verify test parameters (RPM, PW) |

| Fluid leakage during test | Loose injector connection; Damaged O-rings; Faulty injector | Tighten injector connections; Replace O-rings; Replace faulty injector |

If you encounter issues not covered in this section, please contact customer support.

10. Garantia i Suport

LAUNCH provides comprehensive support for the SmartSafe CNC605A.

- Garantia: For damage caused by non-human factors, LAUNCH promises to resend parts for free within 1 year from the date of purchase.

- Idiomes admesos: The unit and documentation support English, Japanese, Russian, Korean, French, Portuguese, Italian, and Chinese.

- Líquid de neteja: Please note that the packaging does not contain cleaning liquid. You can purchase compatible cleaning liquids from most automotive suppliers.

- Atenció al client: For technical assistance, warranty claims, or further inquiries, please refer to the contact information provided with your purchase or visit the official LAUNCH weblloc.